Personal Project Overview

Multi-Axis FDM Printing

The work introduces a novel approach to enhance conventional three-axis FDM 3D printers, enabling the production of pseudo 5-axis geometries through innovative work holding components. By addressing limitations such as overhangs and bridging, this method expands the capabilities of existing machines without the need for costly upgrades. Unlike complex open-source five-axis projects, this technique simplifies the process while improving material properties and directional strength, particularly beneficial in aerospace applications. Through various demonstrations, including printing a turbine blade, the versatility and adaptability of this approach are showcased, marking a significant step towards democratizing advanced manufacturing techniques and fostering innovation in 3D printing. Read more Here.

Interfacial Stability of Multi-Material FDM 3D Printing Polymers.

Conducted an investigation into the compatibility of common FDM 3D printing polymers with regards to multi-material printing. You can find more information regarding this project here.

Microfluidic Collider

Exploring the interface between microfluidics and art and enjoying some creative time in the lab.

Casino on a Chip

A set of non-deterministic capillaric microfluidic chips similar to the games found at carnivals and casinos. This exercise was conceptualized during a GRC dinner over several glasses of wine. The idea was to create microfluidic capillaric chips with uncertain outcomes upon which the partici- pants could place traditional bets. Preliminary sketches have been drawn up, but no fabrication or realization of the designs has been undertaken as of yet. The current designs leverage the abilities of 3D printing to make previously impossible designs. More info here.

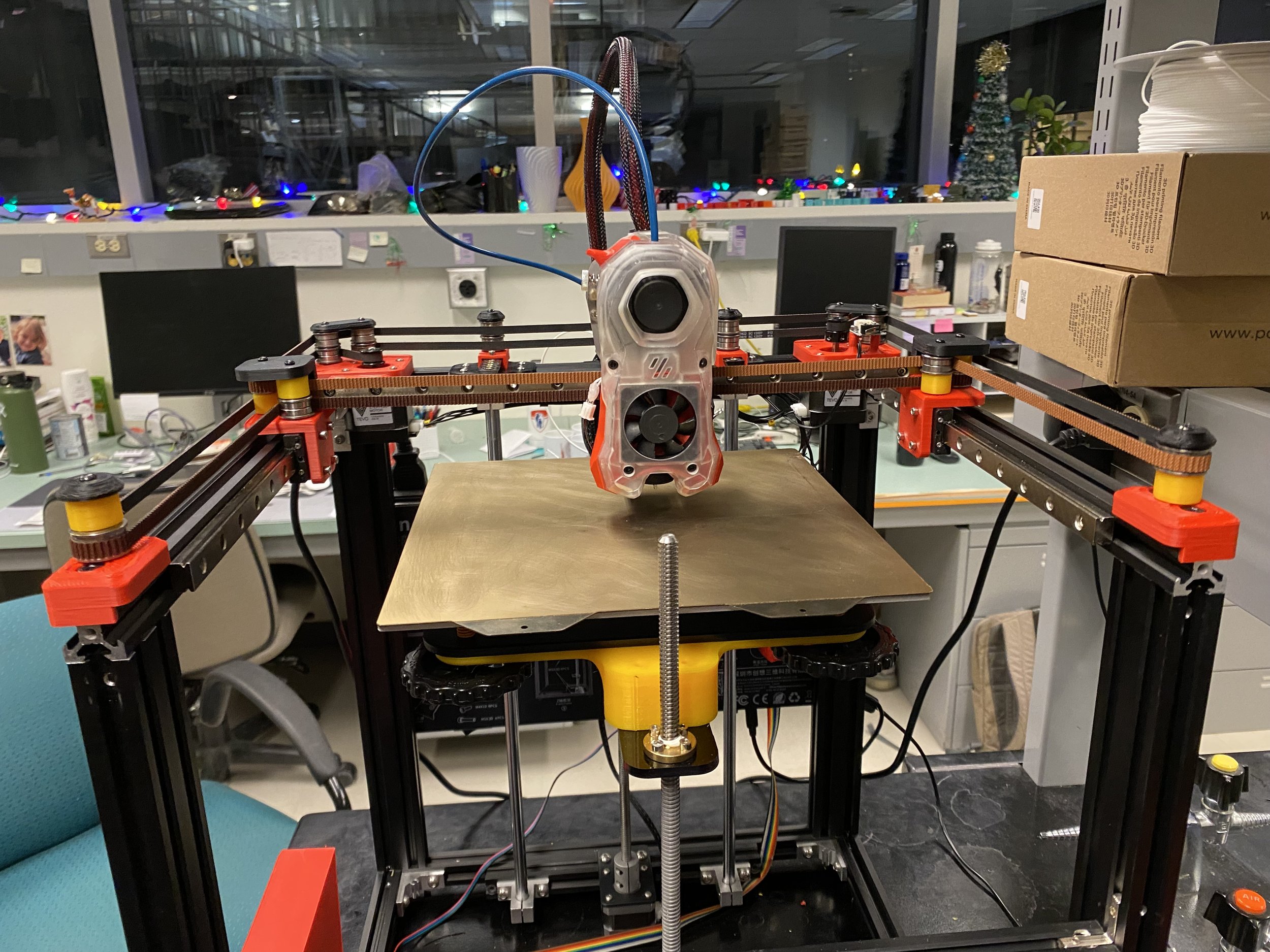

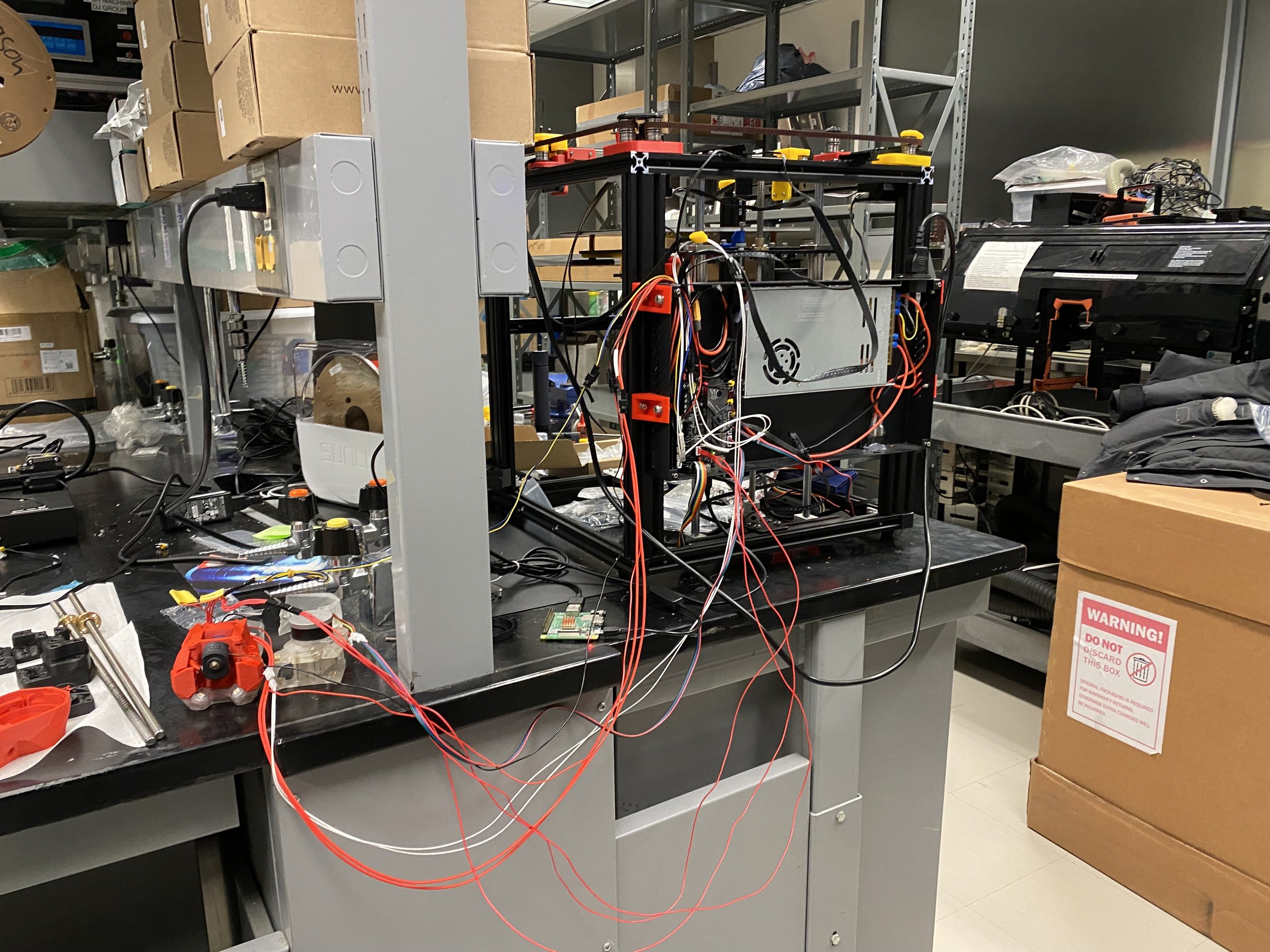

HevORT 5-Axis 3D Printer

Assembled and upgraded a HevORT 3D printer designed by MirageC. A printer designed for reliable high speed printing with tight tolerances. The kinematic bed allows the printer to move in 5 axes, preparing it for next generation slicing engines. This printer was utilized for many experiments including the Multi-Axis FDM and the Stability of Multi-Material Interfaces projects.

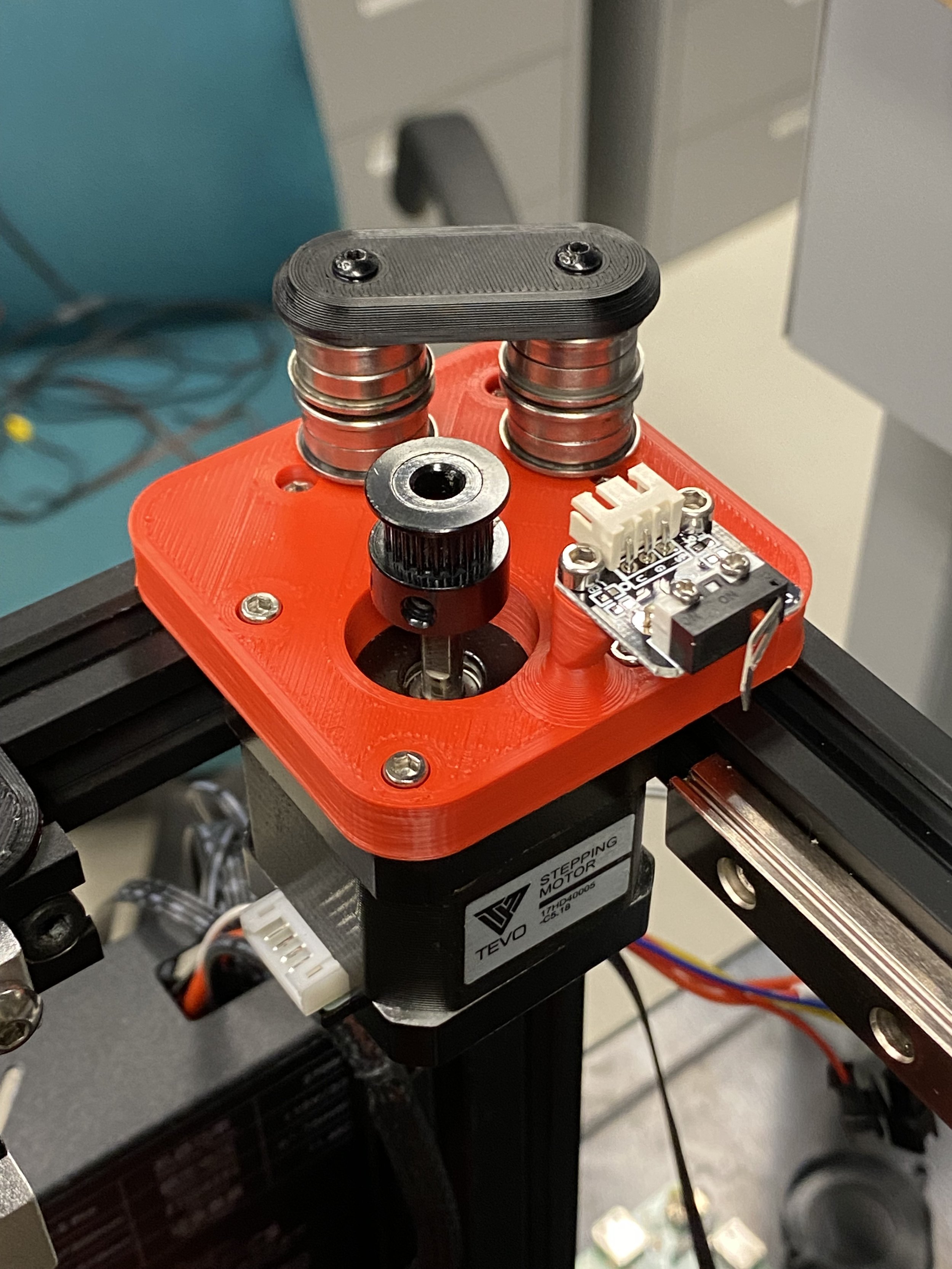

Custom Core-XY Kinematics System

Designed and built a custom Core-XY style kinematics system for a modified Ender 5 3D Printer.

Modifications include:

BTT SKR MINI E3 V3.0 32 bit board

Raspberry Pi running Klipper & Mainsail

Dual Z axis with 42-34 stepper motors

MGN12 linear rails

Voron Stealthburner implementation with neopixel LED illumination & Phaetus Dragonfly Hotend

Wind tunnel for air filtration testing

Part of my Masters thesis involves the testing of a device requiring airflow through it. For this purpose I have gone through multiple iterations to satisfy the needs of that project and learned many useful CAD techniques along the way. Masters Thesis.

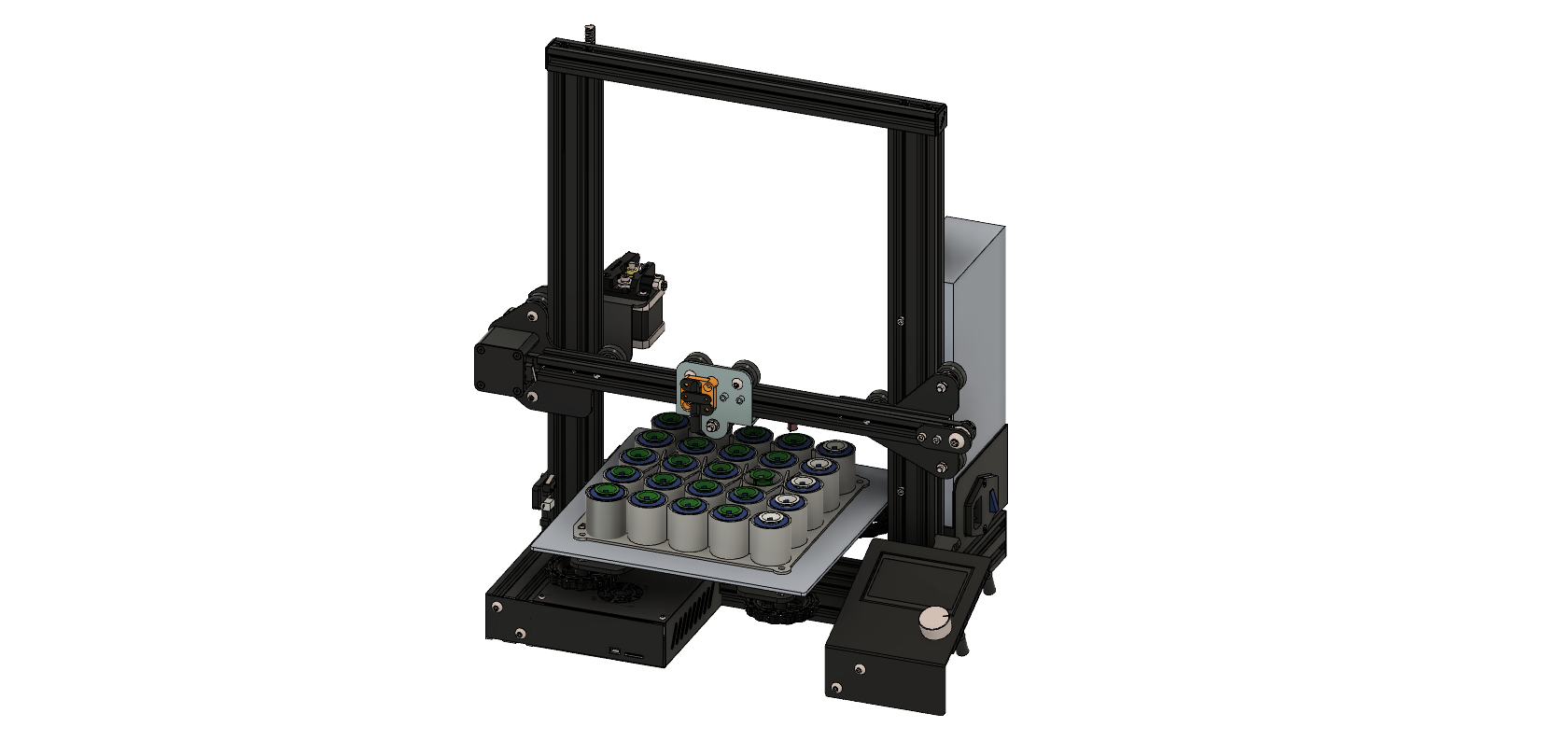

Modified Ender 3 for microscopy and microfluidic autosampling

Designed an upgrade for a Ender 3 to serve as a auto-sampler between 25 different liquid solutions for automated washing, rinsing and labelling steps within complicated microfluidic operation. Capacity for variable inserts to accommodate different sized fluid receptacles, Device can be controlled through python scripts running directly within the microscope software.

Resin 3D printing calibration chips

Quality control and reproducibility are very important and so I designed calibration chips for the assessment of different facets of resin based printer operation. One chip was designed specifically for microfluidics containing embedded and open faced channels and another chip with more general surface features for calibration.

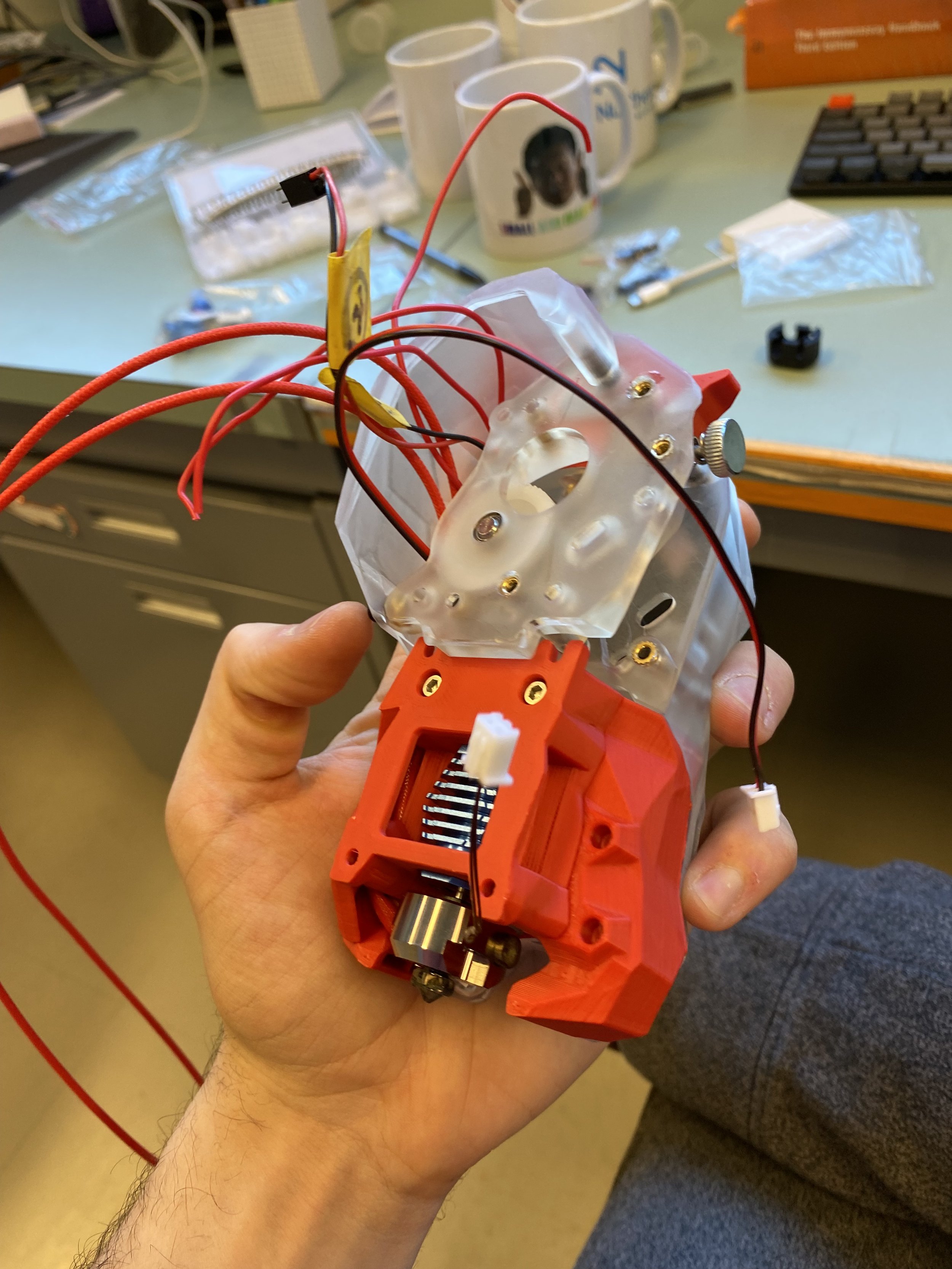

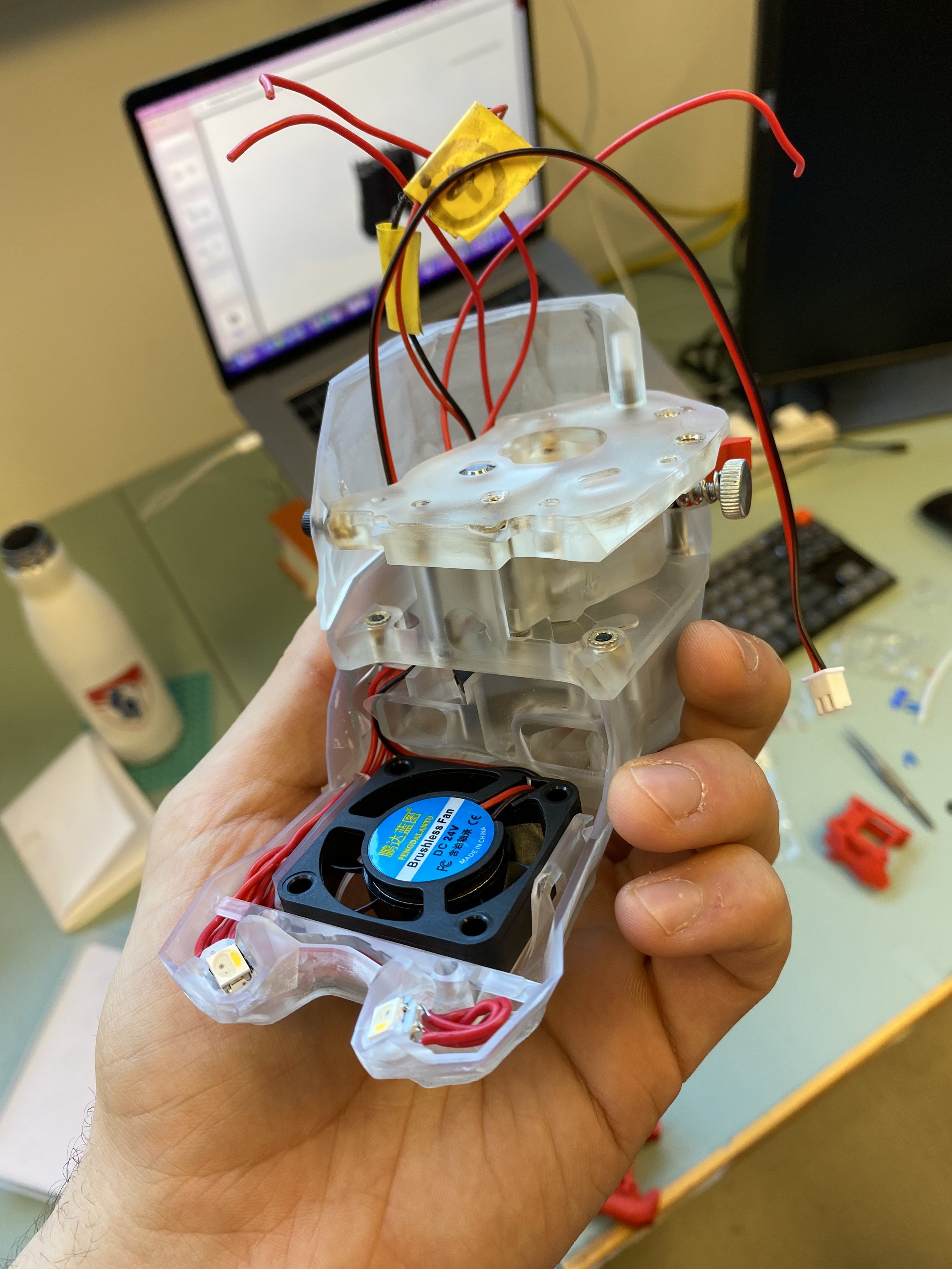

High-Flow Upgrade for Ender 5

Designed and fabricated an improved hot-end and extrusion system for a Ender 5 3D printer with micro-swiss direct drive addition. Utilizes 2x 5015 radial fans for part cooling and a standard 40x40 fan for heatbreak cooling. This solution provides improved cooling to a highflow extrusion platform.

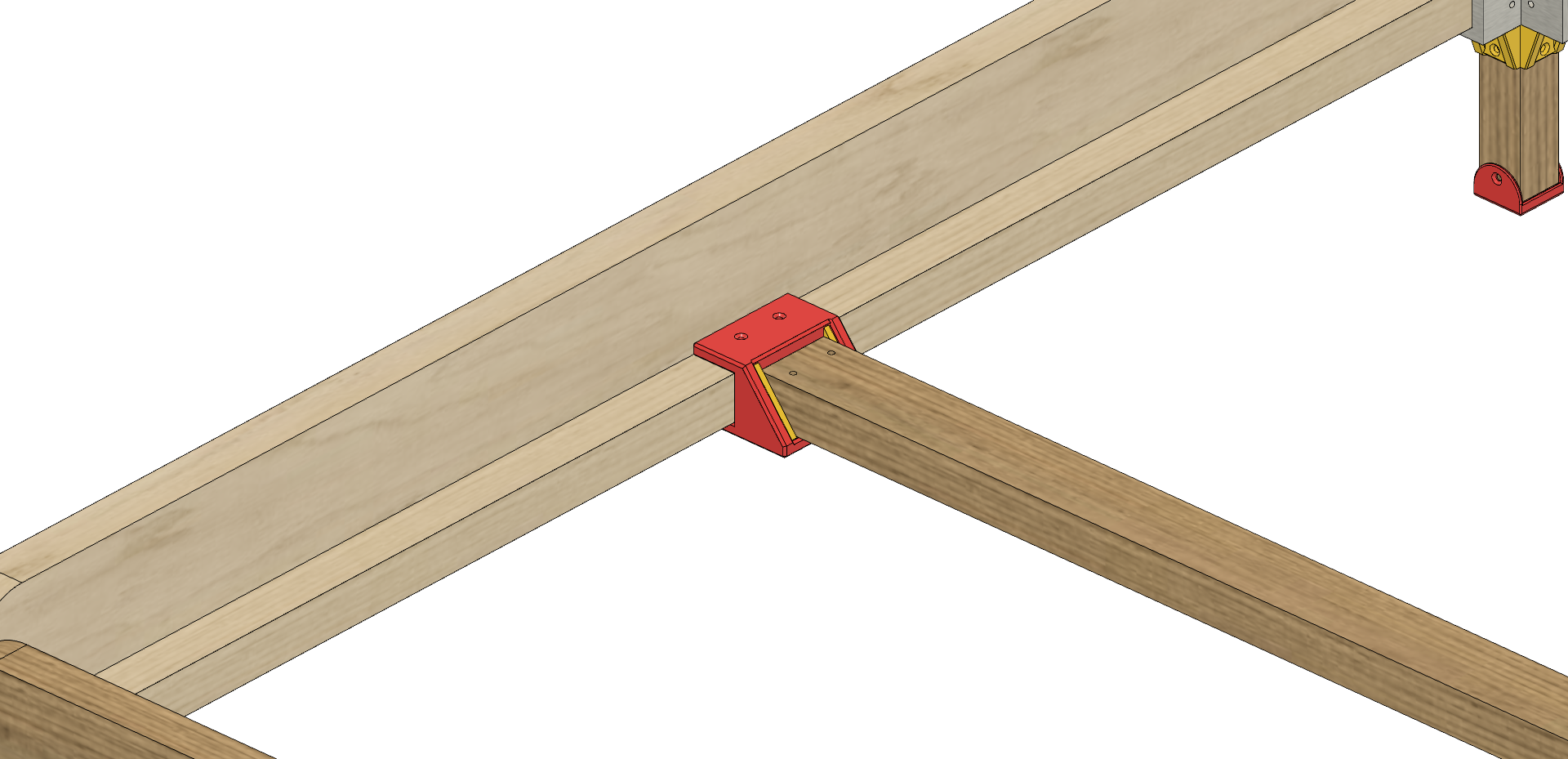

Custom adjustable bed with wireless phone and watch charging

This process was completed from beginning to end over a month. Designing all the components, wood sourcing and shaping, 3D printing parts out of PETG and PLA, custom machined aluminum corner pieces, slats and wireless charger unit from IKEA.

Learning & useful designs

Designs that I composed and printed while learning computer aided design in early 2019.